Sancassiano Horizontal Continuous Mixer

Sancassiano Horizontal Continuous Mixer

Contact us for price

Location:United States

Description

The Continuous mixing system produces from 1.000 to 10.000 kg/h of fresh dough.

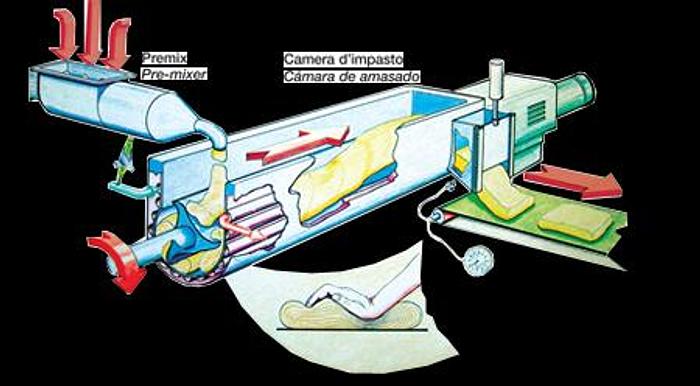

Sancassiano range of continuous mixers has recently been completed with a continuous mixer in horizontal design.

The central part of the process, the proper kneading phase, is in this case done with the use of an horizontal mixing tool set in an horizontal mixing chamber. The dimensions of the horizontal chamber vary according to the throughput required.

From the pre-mixer the homogeneous mix of ingredients is introduced at one side of the kneading chamber where an horizontal tool is responsible for the proper kneading action. When it is ready the dough exits on the opposite side of the mixing chamber.

Where the dough exits the horizontal mixing chamber, the opening is variable and this is controlled at the PLC. In this way the time the dough will be mixed for in the kneading chamber can be controlled.

The speed of the horizontal tool set is also controlled at the PLC.

With the total control over mixing parameter, it is possible to create the optimum setup for a wide range of products, such as croissant, baguette, pizza, etc.

Advantages of the Horizontal Continuous Mixer:

Low dough temperature.

Controllable mixing intensity.

Mechanical sturdiness.

Total management of the process.

The main advantage of the Horizontal Continuous Mixer, is its ability to efficiently cool the dough; it will maintain a high level of temperature control even when the temperature of the finished product is around 12°C. This is thanks to the circulation of a temperature controlled glycol mix in the jacket of the kneading chamber.

Specifications

| Condition | New |